About Swisstrax /

Swiss Engineered

Swiss engineering conveys the idea of precision, well-crafted goods that are long-lasting and durable. We’ve built a line of unique modular flooring tiles that offer the finest in Swiss engineering, combined with American Made quality. Every day we strive to offer customers the best-in-market solution for interlocking floor tiles, while providing the top class customer service through our Flooring Specialists. Discover more about Swisstrax products and how we got started in the industry.

Industry Leader Of Tile Solutions

Learn more about how Swisstrax got started and its continued growth throughout the world. From its inception, Swisstrax focuses on offering the world’s finest modular flooring solution for a variety of applications.

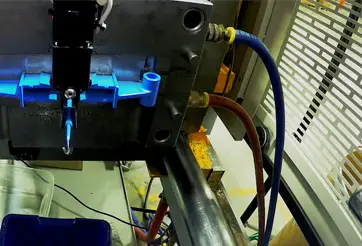

State-of-the-art Injection Molding Presses

Our new fully electric injection molding presses drastically cut down on our overall production time, while maintaining the integrity and reliability of Swisstrax tile solutions that our customers have grown to expect.

While improving our production process is very important to our company, we also want to make sure that we are improving our manufacturing capabilities in an environmentally responsible way.

Industry-leading Processes

Challenge

Swisstrax utilizes an industry-leading process whereby each modular flooring solution checked for quality, flatness and color consistency prior to shipment. The process is primarily used to simplify installation and ensure quality, but it has also helped the Swisstrax team identify any small imperfections or slight fluctuations in color. While these issues could be addressed prior to shipment, doing so required additional assembly time to replace tiles.

SOLUTIONS

Improvements In Color Consistency

A gravimetric dosing system replaced the current volumetric dosing system improving the color consistency of each tile and reducing the overuse of expensive colorants.

New Electric Injection Molding Presses

A move to state-of-the-art electric injection molding presses reduced overall power consumption during the manufacturing process by up to 70% compared with previous hydraulic systems.

Energy Reducing Solutions

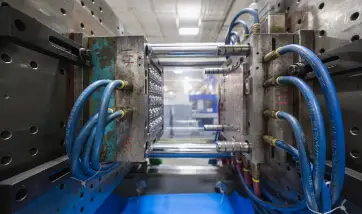

An innovative closed loop process cooling system was employed to decrease cycle time while greatly reducing energy costs.

QUALITY CARE AND IMPROVEMENTS

All molds were cleaned and adjusted to improve both cycle time and quality.

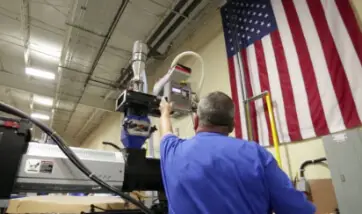

An Increase In Productivity

Robotics were installed to increase productivity and provide more dependable cycle times.

Get Free Design Assistance

A manufacturing process which empowers its team members to focus on quality and continual improvement was employed.

Affirm can only be utilized with purchases made through the Swisstrax sales team, not on the Swisstrax online store.

Payment options through Affirm are subject to an eligibility check and are provided by these lending partners: affirm.com/lenders.